May 02, 2025

In today's technology-driven world, managing electromagnetic interference (EMI) is crucial for ensuring the reliable performance of electronic devices. Custom RF shielding solutions play a vital role in creating controlled environments that block unwanted radio frequency (RF) signals. While commercial RF shield boxes are widely available, there are instances where building a custom solution is the better choice. This article explores when and why you might consider constructing your own RF shield box.

An RF shield box is an enclosure designed to prevent external RF signals from entering and to contain internal emissions. These enclosures are essential for testing wireless devices, ensuring accurate measurements, and preventing unintended signals from affecting nearby equipment. Industries such as telecommunications, medical devices, and consumer electronics frequently use RF shield boxes to comply with regulatory standards and maintain device reliability.

1. Unique Testing Requirements

Commercial RF shield boxes are designed for general applications, but some testing scenarios require a tailored solution. If a device has unconventional dimensions, specialized access points, or specific attenuation needs, a custom RF shielding solution allows for precise adjustments that meet these unique requirements.

2. Budget Considerations

High-end RF shield boxes can be expensive, especially for small-scale operations, research projects, or startups. A custom-built shield box can be a cost-effective alternative, offering similar performance without the high price tag.

3. Rapid Prototyping and Research

In product development, quick iterations are often necessary. Constructing a custom RF shield box allows engineers and researchers to modify the design as needed, reducing lead times associated with ordering specialized commercial units.

4. Educational and Training Purposes

For universities and training programs, building RF shield boxes provides students with hands-on experience in EMI/RFI shielding. This practical learning approach helps students understand electromagnetic compatibility (EMC) principles in a real-world setting.

1. Customization

A custom RF shielding solution allows you to design an enclosure that fits your specific needs. You can determine the optimal size, layout, and features, such as access points for cables, ventilation, and shielding effectiveness.

2. Material Selection

Choosing the right materials is essential for effective shielding. Copper, brass, nickel, silver, steel, and tin each provide different levels of conductivity and permeability. Selecting the appropriate material ensures that your RF shield box meets the necessary performance standards.

3. Hands-On Learning and Skill Development

The process of designing and constructing an RF shield box deepens knowledge of EMI principles. Engineers, technicians, and students gain valuable experience that can be applied in various industries.

4. Scalability

For projects requiring multiple shield boxes, designing one custom model can streamline production. Once a prototype is validated, replicating the design for future use becomes more efficient and cost-effective than purchasing commercial units.

1. Design and Construction

The effectiveness of an RF shield box depends on precise design and careful construction. Key factors to consider include:

• Properly sealing seams to prevent signal leakage.

• Using appropriate gaskets for doors to maintain shielding integrity.

• Designing cable entry points that allow access without compromising performance.

Even small gaps can significantly reduce the shielding effectiveness, making attention to detail crucial.

2. Selecting the Right Materials

Material properties play a critical role in shielding effectiveness. Highly conductive metals such as copper and silver are excellent at reflecting electromagnetic waves, while materials like steel offer magnetic permeability beneficial for certain applications. The choice of material should align with the frequencies of interest and the level of attenuation required.

3. Testing and Validation

After construction, testing is essential to ensure that the RF shield box meets the required attenuation levels. Common testing methods include:

• Using a spectrum analyser and signal generator to measure shielding effectiveness across different frequency ranges.

• Checking for any unintended leakage that might affect performance.

Validation ensures that the custom RF shielding solution performs as expected under real-world conditions.

4. Safety Considerations

Proper grounding is necessary to prevent electrical hazards. Additionally, ventilation should be incorporated without compromising the shielding capability. Ensuring these safety measures protects both the user and the equipment.

Building a custom RF shield box provides flexibility, cost savings, and hands-on learning opportunities. Whether your motivation is unique testing requirements, budget constraints, or research needs, a custom RF shielding solution can be a practical and effective alternative to commercial options. By carefully considering design, material selection, and testing methods, you can construct an RF shield box that meets your specific needs while ensuring reliable performance for electronic devices.

Previous Blog

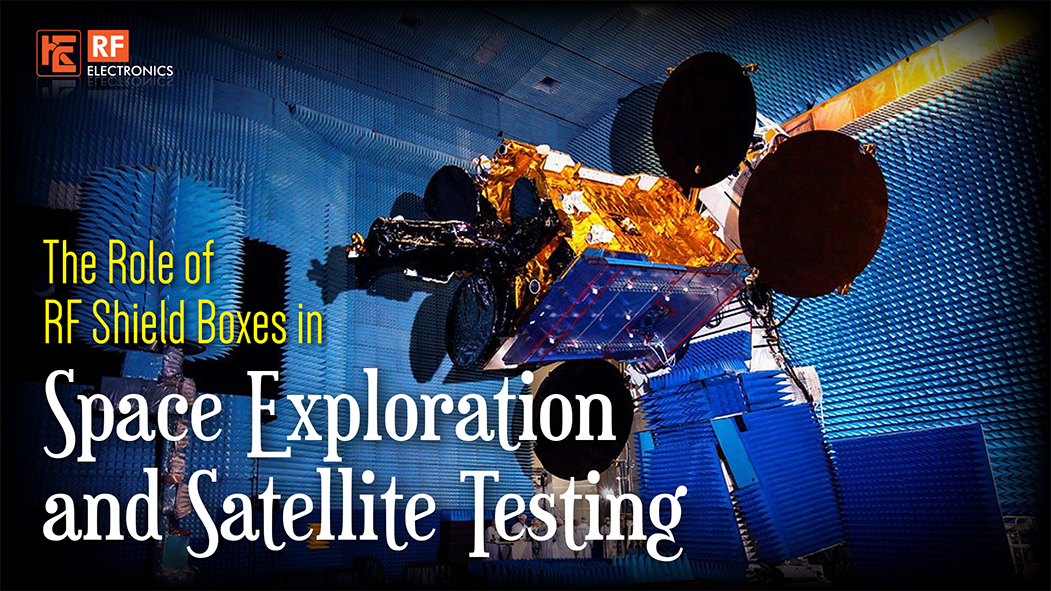

The Role of RF Shield Boxes in Space Exploration and Satellite Testing

Learn MoreNext Blog

Portable RF Shielding Solutions - When and Why You Need Them

Learn More