Our facility is designed to ensure superior quality of research, high-tech production techniques, secured storage and advanced packaging

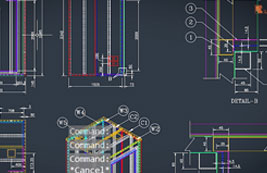

Experienced and Highly Skilled In House CAD Design Team having ability to create Complex Custom CAD design solutions with quick turnaround time; ideal for short project timelines.

RF Electronics has a very well established end to end Fabrication and assembly and test pipeline ensuring use of precision tools and parts used in the product design are qualified with state of art equipment in house. With a skilled workforce and multiple quality check points at every stage.

RF Electronics has setup Conducted Emissions Test Setup to ensure quality compliance of filtered I/O modules and accessories used inside the Shield Box with the International standards.

RF Electronics maintains ENA ( DC ~ 40GHz ) as In-House Capital Asset.

RF Electronics has also created its own state of the art Robotic Radiated Emissions Test Setup (RRETS) to get quick turnaround time with increased testing precision for characterizing the isolation of Shield Boxes. This eliminates process variations and human errors while achieving precise test measurement results with repeatability.

RF Electronics maintains many more state of the art manufacturing and compliance machinery to ensure upto the standard end to end manufacturing process.